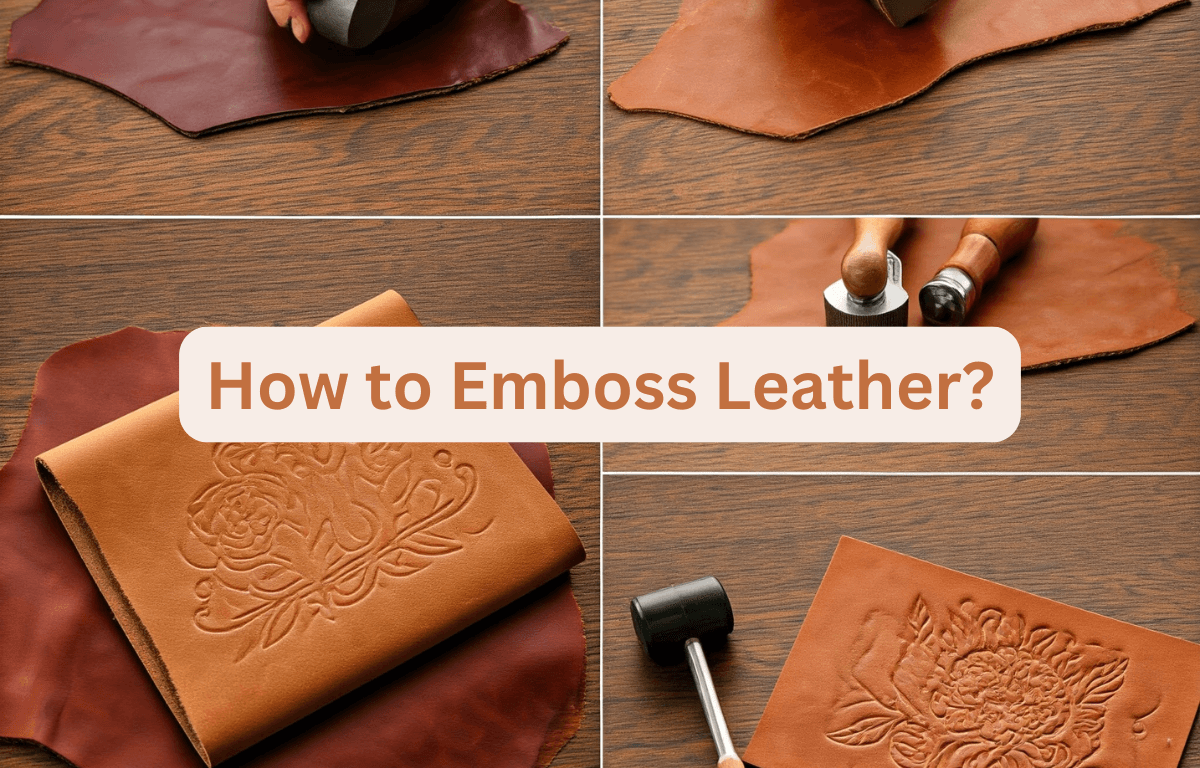

How to Emboss Leather?

From the depths of history, leather embossing arose to meet both practical demands and artistic yearnings. Craftsmen discovered its diverse potential: it could brand their work, strengthen the material's durability, add crucial grip to everyday items, and transform simple leather into intricate works of art.

Fast forward to today, while modern methods often utilize machinery, the core principles of personalization, durability, and aesthetic enhancement continue to drive its application in the production of high-quality leather goods.

What Is Leather Embossing?

Leather embossing is a technique used to create raised or recessed designs on the surface of leather by applying pressure, often with heated metal stamps or rollers. This process allows for the imprinting of intricate patterns, logos, or inscriptions onto leather goods, enhancing their aesthetic appeal and adding a unique touch, and to add visual interest, improve grip, hide imperfections, and enhance the durability of leather products. It is also commonly used for branding purposes, as embossed logos and monograms can instantly identify the manufacturer or designer.

From subtle maker's marks to elaborate decorative patterns, embossing has been employed for centuries to personalize and enhance leather goods, ranging from fine bookbinding and luxury accessories to practical items like saddles and boots.

Why Emboss Leather: Understanding the Basics?

Leather embossing offers a multitude of benefits beyond mere decoration. It serves multiple vital purposes, transforming raw leather into enhanced products that combine functionality with visual appeal. At its core, this technique strengthens the material by compressing leather fibers, creating more durable sections that better resist wear and tear – particularly crucial for high-stress areas in items like leather bags, saddles and footwear

Aesthetics & Branding: Embossing adds visual depth and texture, elevating the look and feel of leather products. It's a prime method for incorporating logos, monograms, and intricate designs, creating a unique and personalized touch. This not only enhances the product's appeal but also serves as a powerful branding tool, instantly recognizing the manufacturer or designer.

Functionality & Durability: Embossing can significantly improve the functionality of leather items. For instance, embossed patterns on gloves can enhance grip, while those on footwear can provide better traction. Furthermore, embossing can reinforce specific areas of leather, making them more resistant to wear and tear, especially in high-stress zones like the handles of bags or the heels of shoes.

Concealing Imperfections: The leather embossing process can help in removing scratches from leather by creating a raised design that masks imperfections. When the embossing technique is applied, it can effectively cover shallow scratches and blemishes, making them less noticeable or even invisible.

Additional Note:

Embossing is a process used to create patterns and textures on leather. For example, Saffiano leather is a type of textured leather that is made using a special embossing process by creating a crosshatch pattern on the leather, giving it a distinctive look. Similarly, the embossing process can be used to add a variety of patterns to top grain leather, such as crocodile, lizard, or snake skin patterns.

On the other hand, patent leather is a type of leather that has a high-gloss finish, achieved by applying a coating that makes it shiny and reflective. While the embossing process can be used on patent leather as well, however, it requires careful handling; the glossy surface can make it more challenging to achieve clear impressions compared to other leathers.

Essential Tools for Leather Embossing

The essential tools for leather embossing can be divided into basic hand tools and modern equipment, each serving specific purposes in the craft. These tools listed below are fundamental for anyone looking to start embossing leather, allowing for both functional and decorative applications in various leather projects.

1. Embossing Machine or Press: A specialized machine that applies pressure to create raised designs on leather surfaces.

2. Metal Dies: Custom-made dies with specific designs or patterns that are used in the embossing process.

3. Heat-Activated Foil (for foil embossing): This adds color and shine to the embossed design when heated.

4. Cutting Mat: Protects the work surface and allows for precise cutting of leather.

5. Utility Knife: Essential for cutting and trimming leather accurately.

6. Awl: Used for marking, making holes, and helping with stitching.

7. Mallet or Hammer: Necessary for stamping and shaping leather, as well as setting rivets and snaps.

8. Hole Punch: Useful for creating holes in leather for stitching or lacing.

Other Essential Tools:

Ruler: For accurate measurements.

Sandpaper: For smoothing leather edges and preparing surfaces.

Leather Dye or Paint: For coloring the embossed designs.

How to Emboss Leather: Step By Step Guide

First of all you must know that each type of leather responds differently to embossing, so always test on a scrap piece before beginning the embossing process. By following steps given below, you will be able to embark on your leather embossing journey and create beautifully embossed leather items that showcase your creativity and craftsmanship.

1. Prepare the Leather

Choose the right leather: Vegetable-tanned leathers like bridle leather, calfskin, and saddle leather are generally the best for embossing due to their density and ability to hold an impression.

Avoid overly soft or thin leathers as they may not hold the embossing well.

Condition the leather (optional): Applying leather conditioner can help soften the leather and make it more receptive to the embossing process.

Clean the leather: Ensure the leather is clean and free of any dirt or debris that might interfere with the embossing process.

2. Design and Prepare Your Embossing

Create your design: You can use your own sketches, transfer existing images using tracing paper, or use pre-made embossing stamps.

Choose your embossing method:

1. Hand embossing: Using hand tools like embossing stamps and mallets.

2. Machine embossing: Using specialized machines for large-scale production or intricate designs.

3. Embossing Process

-

Hand Embossing:

-

Position the stamp: Place the embossing stamp on the leather where you want the design to appear.

-

Strike the stamp: Gently tap the stamp with the leatherworking mallet. Use even pressure to avoid uneven impressions.

-

Repeat: Continue striking the stamp until the desired depth of the impression is achieved. Be careful not to over-emboss, which can damage the leather.

-

-

Machine Embossing:

-

Follow the manufacturer's instructions: Different machines have specific operating procedures.

-

Adjust pressure and temperature: These factors will influence the depth and clarity of the embossing.

-

4: Check Your Work

Carefully lift the stamp or platen and inspect your embossed design. If it's not deep enough, you can repeat the process for a more pronounced effect.

5. Finishing Touches

-

Clean the embossed area: Gently wipe away any excess leather dust or debris.

-

Apply dye or paint (optional): You can color the embossed areas to enhance the design.

-

Condition the leather (optional): Apply leather conditioner to protect the embossed area and keep the leather supple.

6. Quality Control

Inspect the embossing for consistency and also check for any flaws or incomplete impressions. Make touch-ups if necessary and allow 24 hours for complete setting before heavy use.

Easy Tips for Perfect Leather Embossing

In order to achieve beautifully embossed leather items that showcase your craftsmanship effectively and perfect leather embossing results, follow the guidelines given below.

1. Always test your design and pressure on scrap leather first – different leathers respond differently to embossing techniques

2. Keep your leather at ideal moisture content - too wet causes blurring, too dry results in cracking or shallow impressions

3. Apply heat gradually and evenly – sudden temperature changes can damage the leather and create uneven patterns

4. Watch your timing – holding pressure too long can cause over-compression, while too short may give shallow results (typically aim for 10-15 seconds)

5. Maintain consistent pressure across the entire design – uneven pressure leads to inconsistent depth in your pattern

6. Choose the right leather weight – 3-4 oz leather typically works best for most embossing projects

7. Consider grain direction – embossing parallel to the leather's natural grain often gives cleaner results

8. Keep your tools well-maintained – clean, smooth tools create crisper impressions

9. Let embossed pieces dry and cool completely before handling – rushing this step can distort your design

10. Store embossed items flat until fully set – this prevents warping or pattern distortion

Common Mistakes to Avoid While Embossing Leather

Embossing leather can elevate your craft, but many artisans unknowingly stumble into common pitfalls that could ruin their projects. From improper temperature settings to inadequate pressure application, these errors can lead to disappointing results. In our comprehensive step by step guide below, we outline the top mistakes to avoid and share expert tips on how to achieve flawless embossing every time.

1. Using the Wrong Leather:

Not suitable leather: Avoid overly soft, thin, or synthetic leathers as they may not hold the impression well. Instead, vegetable-tanned leathers like bridle leather, calfskin, and saddle leather are generally best.

2. Inadequate Leather Preparation:

- Skipping cleaning: Dirt or debris can interfere with the embossing process.

- Not conditioning (optional): Conditioning can soften the leather and improve embossing results.

3. Incorrect Tool Usage:

-

Using the wrong tools: Ensure you have the right embossing stamps, mallets, and cutting tools for your project.

-

Applying uneven pressure: Consistent pressure is crucial for a clean and even impression.

4. Design and Placement Issues:

-

Poor design choices: Avoid overly complex or intricate designs for beginners.

-

Incorrect placement: Plan the placement of your design carefully to avoid awkward positioning.

5. Over-Embossing:

Excessive pressure: Applying too much pressure can damage the leather and create an undesirable effect.

6. Rushing the Process:

-

Insufficient practice: Practice on scrap leather before working on your final project.

-

Skipping steps: Following the proper steps is essential for achieving good results.

7. Neglecting Safety Precautions:

-

No eye protection: Always wear safety glasses to protect your eyes from flying debris.

-

Working without a cutting mat: A cutting mat protects your work surface and prevents tool damage.

By being mindful of these common mistakes, you can significantly improve your leather embossing results and avoid frustration.

Additional Tips:

-

Start with simple designs: Begin with basic patterns and gradually increase complexity.

-

Experiment with different techniques: Try varying pressure, using different stamps, and exploring different leather types.

-

Be patient and persistent: Leather embossing requires practice and patience. Don't get discouraged if your first attempts aren't perfect.

Conclusion

To sum up, leather embossing is a versatile technique that enhances both the aesthetic and functional qualities of leather goods. By understanding the fundamentals, selecting the right tools and leather, and practicing proper techniques, you can create beautiful and unique leather pieces. Remember to avoid common mistakes like using unsuitable leather, applying uneven pressure, and neglecting safety precautions. With patience, practice and attention to detail, embossing can elevate the craftsmanship of leather items as well as you can master the art of leather embossing and unlock its creative potential.

FAQs - How To Emboss Leather?

Can You Emboss Leather Yourself?

Yes, you can definitely emboss leather yourself at home with the right tools and techniques, and practice.

What Can You Use To Emboss Leather?

You can use tools such as embossing stamps, metal dies, a mallet or hammer, and an embossing machine to emboss leather.

How Do You Emboss Leather Manually?

Manual leather embossing typically involves pressing embossing stamps into the leather using a mallet, creating a clear impression and design.